Cold formed steel refers to steel products formed at room temperature through a process of bending or shaping sheets of steel. It is commonly used in construction for framing, wall studs, roof trusses, and other structural components because of its strength, durability, and low cost.

A cold formed steel building is a structure constructed primarily using cold formed steel members.

Cold formed steel is made by rolling or pressing thin sheets of steel to form various shapes such as studs, beams, channels, and angles.

These steel members are then assembled and connected to create the framework of the building. Cold formed steel buildings are known for their durability, strength, and versatility.

They are often used in a variety of construction projects including residential, commercial, industrial, agricultural, and even institutional buildings. Because it is a reliable construction material and simple to install, cold formed steel is rapidly dominating the construction industry.

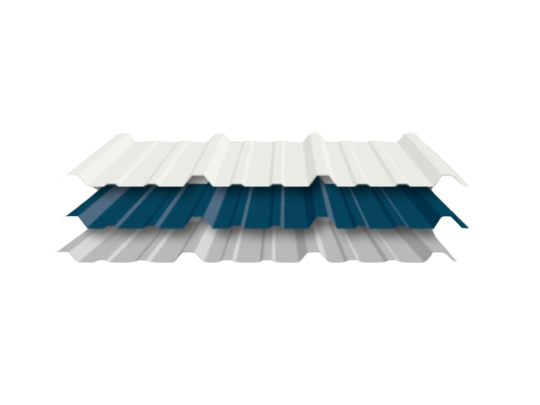

Durability, rugged design, and maximized usability are what auto repair shops, vehicle dealerships, retail stores, RV garages, welding shops, or any other commercial businesses expect from their prefabricated steel buildings. Nothing is more durable than our Galvalume Plus™ coated steel buildings, rest assured that your solution will stand the test of time every time.

When searching for the perfect steel solution for your project’s needs. You need a structure that is not only functional and efficient but also durable and affordable. Our team of building specialists and engineers will always go the extra mile when finding you the perfect structure to fit your exact needs.

Our clear span design is specifically engineered to use the maximum amount of “airspace” possible, in order to maximize storage. The column-free interior design creates an open concept building. Choose from a variety of roof and siding styles, from double-sloped to single, to tapered and non-tapered.

Our Multi-span frames are commonly used for building layouts that permit interior columns. The spacing of each column can be customized to meet any specific needs, large open floor spaces can be accommodated by using the minimum number of columns. This allows for open and closed-off separate spaces to be customized within the structure, making it easy for the movement of large equipment.

Primarily used for extension and expansions of existing structures in Canada, our lean-to frames can provide additional space very economically. A lean-to frame style building must be supported by its attachment to another frame. This style is commonly used to provide additional storage or garage space. This is perfect for those wanting to expand the space of their already existing rigid frame building.

We offer quality and cost-effective steel building accessories manufactured in Canada to complete your project.

Construct the building of your dreams and express yourself with our various colour options, customize the entire look of your building by selecting the corner colour, eave colour, wall colour, gable colour, jamb colour and roof colour.

Available for CFS and I-Beam Buildings.

Collects and transports precipitation safely away from the building.

Premium heavy duty blanket insulation with added abuse resistance. Blanket insulation is made up of small fibres, used in floors, ceiling, and inside of walls.

Liner panels are interior walls of steel paneling. Similar to exterior walls, they consist of standard 3-foot wide panels (usually 29 gauge) that are screwed to the framing. Full-height liners run from floor to roof and attach at the top to the eave struts on the sidewalls and to the rake rafter on endwalls.

Our flat slab, frost-protected floating foundations utilize high strength steel to resolve common issues that arise from building on environmentally sensitive land, extreme frost, variable soil conditions, high static water, remote site locations, and tight budget installations.

Ready-made doors including hangar, sliding, sectional overhead, the convenient 4×7 service door. Built to your specifications or just use a frame to install your favourite custom door.

Bring in natural light to reduce your lighting bills while adding aesthetic appeal to the exterior of your building. Self-flashing and self-framing aluminum windows are available with Thermal Break or Non-Thermal Break frames.

Cold formed steel offers competitive pricing in comparison to wood.

However, it is important to consider more than the upfront price. Though wood is one of the cheapest building materials you can use, it is highly vulnerable to water damage, termite infestations, and lacks energy efficiency.

This leads to significant expenditures on repairs and preventative measures over time. Cold formed steel has a much longer lifespan, requires little maintenance or repair, and is one of the most sustainable building materials.

Cold formed steel framing is recognized for its lightweight nature. Steel inherently possesses a low density, meaning there is a low concentration of steel present. However, this does not compromise its strength, longevity, and effectiveness.

The lightweight attribute of cold formed steel stands as one of its primary benefits. Because these components are so light, it facilitates easy transportation and installation of components.

And beyond simplifying the construction process, the use of lightweight materials like cold formed steel also translates to cost-effectiveness.

Cold formed steel is a versatile option for various types of buildings. It excels in projects requiring efficient design, structural integrity, and cost-effectiveness. Cold formed steel is commonly used for residential, commercial, industrial, institutional, and agricultural buildings.

Cold formed steel buildings are known for their durability, strength, and resilience. They are engineered to withstand a wide range of weather conditions, including high windows, seismic events, and heavy snow loads. Cold formed steel buildings are carefully designed and manufactured to meet specific requirements in order to maintain their structural integrity.

Cold formed steel buildings are designed with flexibility in mind, allowing for relatively easy modifications or expansions in the future. The lightweight nature of cold formed steel components allows for modifications without significant structural changes. This adaptability makes them a favourable choice for steel building projects requiring future modifications or expansions.