What if the real cost of your cold storage isn’t the price tag… but the money you’re losing every day?

For many businesses, cold storage is the backbone of operations. Yet the wrong system drains cash in ways you don’t see until it’s too late. Energy bills creep higher. Repairs eat into profits. Downtime spoils product and trust.

Steel cold storage may feel like a bigger upfront expense. But here’s the truth: when you calculate its efficiency, durability, and risk reduction, it often costs less than cheaper alternatives.

In this article, we’ll break down the numbers, expose hidden savings, and show how steel cold storage protects your margins. If you’re serious about long-term growth and stability, the investment may not just pay for itself it may secure your future.

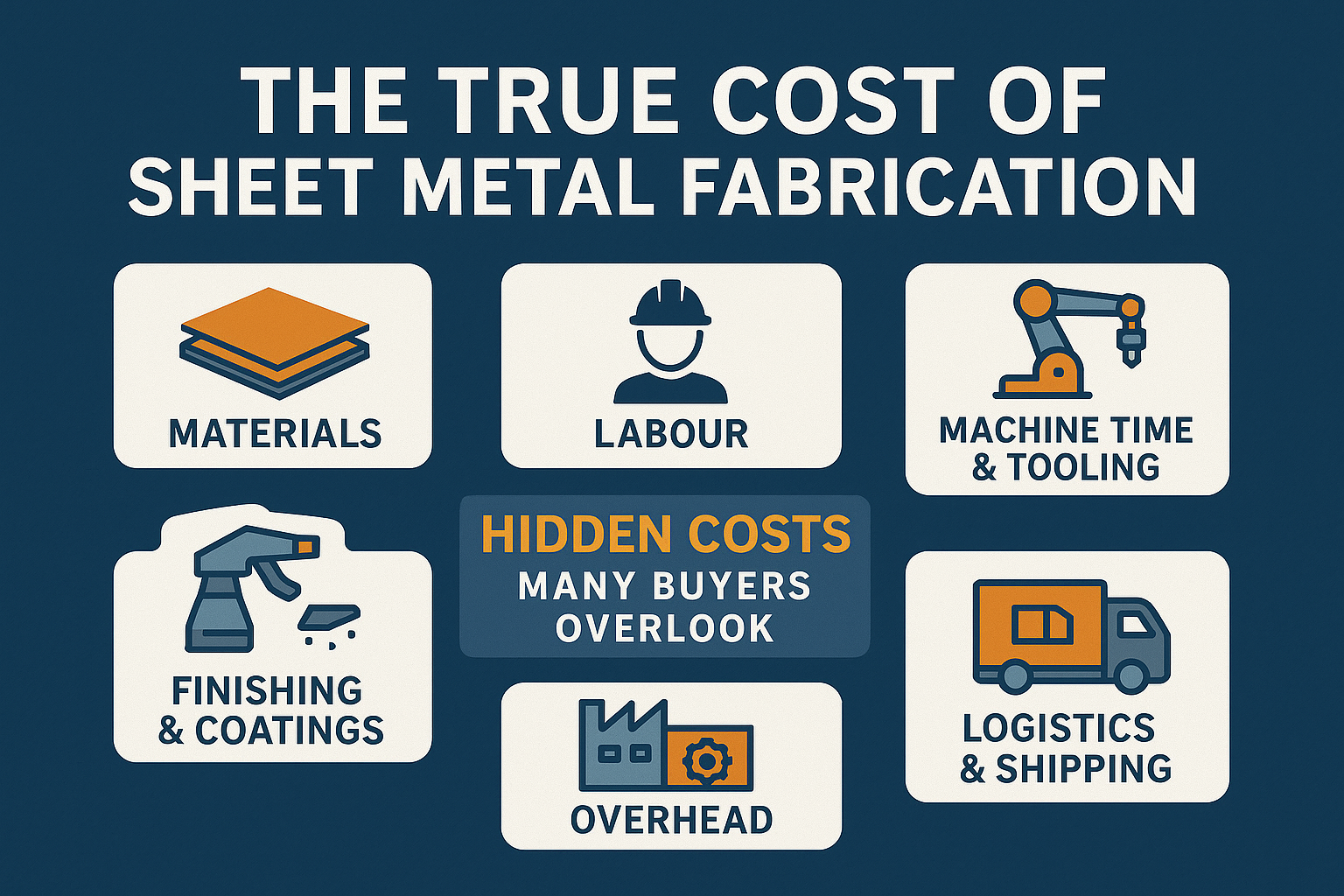

Breaking Down the Real Cost of Steel Cold Storage

CAPEX (Upfront build).

In Canada, cold rooms typically run $100–$300 per sq ft. That range covers insulation, refrigeration, and specialized doors. Steel structures with insulated metal panels (IMPs) help you hit performance targets with fewer layers.

For larger greenfield facilities, many owners still budget ~$130–$350 per sq ft depending on temperature band, layout, and site. Treat this as a planning band, then refine with design.

Modern IMPs used in Canadian cold storage deliver R-values from ~R-5 to R-64, supporting deep-freeze specs with thinner walls.

OPEX (Energy + maintenance).

Power prices vary by province. As of April 1, 2024, large-power average prices were about 5.74 ¢/kWh in Montréal, 8.12 ¢ in Vancouver, 10.90 ¢ in Toronto, and 13.17 ¢ in Edmonton. Your site’s bill will follow the local utility.

Refrigeration is the big load. Studies show ~60–70% of electricity in cold storage goes to cooling. Efficiency here moves the needle most.

Industry guidance in Canada also stresses predictive maintenance and electrical reliability to keep costs and downtime low.

Using high-R, continuous insulation (IMPs) reduces thermal bridging. That eases compressor runtime and lowers utility spend.

TCO (10–20-year ownership).

Total cost blends CAPEX, energy, upkeep, and risk. Steel + IMP envelopes resist moisture and damage, so maintenance is simpler and performance stays stable over years.

Electricity is a recurring cost, so provincial rates matter. Facilities in hydro-dominant provinces often see structurally lower OPEX, improving payback on high-efficiency builds.

Benchmarking tools from Natural Resources Canada help owners model usage and spot savings across refrigerated spaces. Use them early in design.

Hidden Savings That Reduce Long-Term Costs

Beyond the upfront price tag, steel cold storage delivers hidden savings that can quickly shift the ROI in your favor.

1. Lower Energy Bills through Superior Insulation & Envelope Design

- Using insulated metal panels (IMPs) or high-R continuous insulation reduces thermal bridging and air leaks. That means compressors run less.

- LED lighting in cold/freezer rooms when optimized for cold temps cuts lighting energy by up to ~75% compared to older HID lamps. Plus, LEDs produce less heat so refrigeration load isn’t fighting excess heat.

- Solar power + battery storage (where feasible) shrinks dependence on grid electricity. This is especially helpful in Canadian provinces with high industrial rates or volatile pricing. Over time, this lowers both utility bills and exposure to rate hikes.

2. Minimal Maintenance and Fewer Repairs

- Steel structures resist rot, pests, water damage better than many wood or less protected materials. That reduces cost for structural repairs and keeps the building envelope tight.

- Fewer surface joints, better door seals, solid metal panels all help reduce leaks where cold air escapes or moisture enters, which can eat up energy and cause corrosion or freezing damage.

- Predictive maintenance and good building management systems reduce surprise breakdowns or emergency repairs, which are expensive and often cause downtime.

3. Extended Lifespan and Durability of the Structure

- Steel + high quality insulation lasts longer with consistent performance. That means fewer renovations, fewer replacements of panels or doors, and lower depreciation.

- Durable materials support warranties longer. Because steel resists weather, moisture, pests better, your structure stays tighter to spec, so energy losses through envelope deterioration are delayed.

- When components wear out (doors, refrigeration, seals), better designs make replacements easier and cheaper standardized steel parts are often more accessible and cost-effective.

Financial Risks Avoided with Steel Cold Storage

When you invest in steel cold storage, you sidestep several serious financial risks. Here are the most relevant ones for Canadian businesses, drawn from regulations, case studies, and real enforcement data.

1. Preventing Costly Downtime and Product Spoilage

- Cold chain failures lead to microbial growth or product degradation. Once temperature or humidity goes off spec, spoilage starts fast.

- When equipment fails or maintenance lapses, the losses aren’t just product costs; they include labor to discard, repackage, or redo shipments plus customer service fallout.

- Steel builds with high-integrity insulation are more resistant to failures (e.g. air leaks, moisture ingress). That keeps temperature steady and avoids unexpected failures. (You reduce risk of spoilage)

2. Ensuring Compliance with Canadian Food Safety & Regulatory Standards

- Canada’s Safe Food for Canadians Act (SFCA) and Safe Food for Canadians Regulations (SFCR) set rules for how food must be handled, stored, and transported. Violations may trigger Administrative Monetary Penalties (AMPs).

- For example, serious violations under CFIA regulation can lead to fines up to $15,000 or more, especially in repeat or harmful cases.

- Worse, in cases of criminal prosecution under the SFCA (for more severe violations), penalties can go much higher: fines up to $5 million and/or imprisonment up to two years.

3. Reducing Liability and Insurance Exposure

- Liability risk includes legal suits if spoiled product harms consumers, or if cold storage failure violates provincial/local health regulations. Even if insurance covers some losses, legal fees, recall costs, and brand damage can dwarf direct costs.

- Regulatory violations remain public record. They hurt reputation, customer trust, and future contracts. Businesses that repeatedly violate food safety or storage standards may lose licenses or face suspension.

- Insurance premiums are generally lower for facilities with strong infrastructure: reliable steel construction, good environmental controls, regular monitoring. Weak or poorly built cold storage can lead to higher rates or even denial of coverage.

ROI and Business Impact

Steel cold storage is a financial decision, not just an engineering one.

Here’s how to quantify the return in a clear, defensible way using Canadian data and standards.

1) What actually drives ROI

- Energy use profile. Refrigeration typically accounts for ~60–70% of a cold facility’s electricity. Improvements that cut compressor runtime move the ROI needle fastest.

- Envelope performance. Tight, high-R assemblies reduce thermal bridging and air leakage, stabilizing temperatures and lowering load. Guidance from Canadian benchmarking programs emphasizes measuring and tracking these outcomes over time.

- Compliance & risk. Adhering to nationally recognized storage temperatures (e.g., ≤4 °C for chill, ≤-18 °C for freeze) reduces spoilage risk, penalties, and write-offs—an indirect but material ROI lever.

2) A simple ROI model you can defend

Use your own meter data and quotes to keep it audit-proof.

Inputs (12-month baseline):

- Annual electricity use (kWh) and blended cost ($/kWh).

- Share of load from refrigeration (%).

- Current maintenance and repair spend ($/year).

- Spoilage/downtime losses ($/year) tied to temperature excursions.

- Proposed build/retrofit cost and expected service life (years).

Core calculations:

- Annual energy savings ($):

kWhbase×refrigeration share×efficiency gain×$/kWh

(With refrigeration at 60–70% of load, even modest gains compound.)

- O&M savings ($): Reduced emergency repairs + planned maintenance efficiencies.

- Risk-adjusted loss avoidance ($): Fewer temperature deviations → less spoilage and rework; align with national temperature guidance.

- Annual benefit ($): Energy + O&M + loss avoidance.

- Simple payback (years): Project cost ÷ Annual benefit.

- NPV/IRR: Discount cash flows over 10–20 years to compare options (use standard government-grade cost-estimating practice).

3) What “good” looks like in Canada

- Facilities that benchmark performance (e.g., through nationally recognized tools) and target refrigeration-specific measures see the clearest ROI because results are tracked against peers and weather-normalized.

- Energy savings vary by climate and hours, but studies of cold facilities consistently show refrigeration dominates the bill so envelope integrity, doors/seals, setpoints, and controls deliver outsized returns.

- Operating discipline matters: poor practices can raise energy use by ~30% versus optimized conditions, eroding ROI; fixing procedures and controls restores gains.

4) How steel cold storage accelerates payback

- Tighter envelopes reduce infiltration and thermal losses, shrinking compressor runtime.

- Durability lowers unplanned repairs over the life of the asset, improving cash-flow stability.

- Compliance support with consistent temperatures cuts spoilage events and the chance of enforcement action.

5) Action checklist to improve ROI now

- Collect 12 months of utility and incident data (kWh, $/kWh, alarms, spoilage). Benchmark it using nationally recognized Canadian references.

- Model three scenarios: status-quo, partial retrofit, full steel build compute simple payback and NPV for each using the same assumptions.

- Target refrigeration first: verify setpoints, defrost strategies, door management, and envelope leakage; prioritize measures that cut compressor hours.

- Validate compliance temperatures (≤4 °C chill, ≤-18 °C freeze) to limit loss exposure and protect brand equity. Track excursions and their costs.

The Strategic Value of Choosing Steel Cold Storage

Aligning with Long-Term Business Growth

- Steel supports growth, not just today but for years ahead.

Clear spans and lighter foundations allow efficient layouts and future changes. - Energy benchmarking tools help you track results and prove savings over time. That makes budgets predictable and defendable.

- A tight, insulated envelope also lowers lifecycle energy use. That aligns with corporate ESG goals and rising disclosure expectations.

Protecting Product Integrity and Brand Reputation

- Cold food must stay out of the danger zone. Canada advises ≤ 4 °C for chilled foods and ≤ –18 °C for frozen storage. Holding these setpoints reduces spoilage and complaints

- Sector-specific rules (for example, meat) require chilling to ≤ 4 °C or freezing to ≤ 0 °C before shipping. Reliable envelopes and doors help you meet these targets.

- Insulated metal panels (IMPs) act as a continuous air, vapor, water, and thermal barrier. Fewer seams mean fewer leaks and steadier temperatures. That protects product quality and trust.

Ensuring Scalability and Adaptability

- Steel frames are easy to modify. You can add bays, re-rack, or shift clear heights as needs change. That flexibility reduces future capex shock.

- IMPs simplify expansions because they deliver structure and insulation in one step. That shortens schedules and limits downtime during add-ons.

- Designing out thermal bridges keeps new and old sections efficient after expansion. That protects your cost base as you scale.

Get Your Custom Steel Cold Storage Cost Analysis

Turn wasted energy into profit.

Lock temps. Scale fast. Own your ROI.

Make your move now:

- Lock your specs and target temperatures.

- Get pricing and a build plan you can defend.

- See expansion paths without starting over.

Go:

👉 Start My Project

🔎 Explore Cold Storage Options